DuraPost® Maintenance

DuraPost® Powder Coating Maintenance Procedure

1. Purpose

This guide outlines the maintenance requirements and procedures for the powder-coated finishes applied to all DuraPost® products by Birkdale. Regular maintenance is essential to: Preserve the protective and decorative qualities of the coating. Prevent premature deterioration of the coating and substrate. Maximize the service life of the product.

2. Scope

This procedure applies to all DuraPost® powder-coated products installed in any environment, including inland, coastal, and industrial areas.

3. Tools and Materials Required

- Warm water

- Mild detergent or soap solution

- Soft cloths or sponges

- Natural bristle brush (for persistent

soiling) - White spirit (for exceptional cases only)

- Clean water for rinsing

Prohibited Materials:

- Abrasive cleaners

- Solvent-based cleaners (excluding white spirit when necessary)

- Volatile spirit-based products

4.Safety Precautions

- Always wear appropriate PPE (e.g., gloves and safety glasses) when cleaning.

- Ensure adequate ventilation when using white spirit.

- Avoid using ladders or equipment that may damage the coated surfaces during cleaning.

5.Cleaning Procedure

1.General Cleaning

- Wash surfaces regularly using warm water and a mild detergent.

- Apply the cleaning solution with a soft cloth or sponge to avoid scratching.

- Rinse thoroughly with clean water and allow to dry naturally.

2.Persistent Soiling

- For stubborn dirt, gently scrub with a natural bristle brush.

- Avoid aggressive rubbing that could damage the coating.

3.Heavy or Oil-Based Soiling

- In exceptional circumstances, use white spirit to remove oil-based contaminants.

- Immediately rinse the area with clean water afterward.

4.Damage or Exposed Substrate

- If any damage exposes the galvanizing or substrate, carry out repairs strictly in accordance with Birkdale’s “Remedial Method.”

- Copies of the Remedial Method are available upon request from Birkdale.

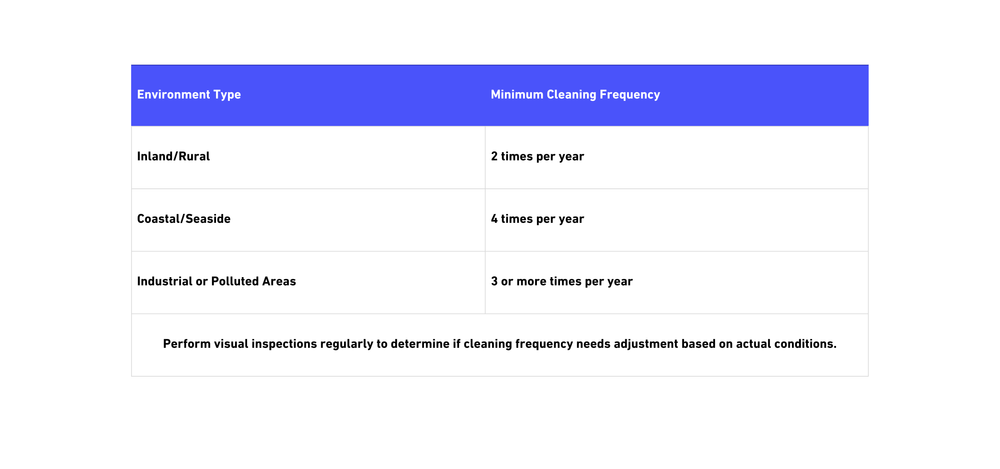

6. Cleaning Frequency

The required frequency of cleaning depends on both the environment and the desired standard of appearance:

7.Environmental Considerations

When establishing a maintenance schedule, evaluate the following factors:

- Proximity to marine or industrial environments.

- Exposure to abrasive airborne particles (sand, dust, etc.).

- Local environmental changes, such as new construction, demolition, or industrial activity, which may alter exposure conditions.

8.Inspection and Record Keeping

- Conduct regular visual inspection to identify:

- Coating damage

- Vandalism

- Environmental wear

- Record each inspection and cleaning including:

- Date of maintenance

- Method and materials used

- Observations and any repairs carried out

All maintenance records must be retained and made available to Birkdale upon request.

9. Summary

Adhering to this maintenance guide ensures the long-term durability and visual quality of DuraPost powder-coated products. Regular inspection, correct cleaning techniques, and prompt remedial action are key to preserving performance and warranty compliance.

BJA Trading Ltd t/a Birkdale 10/25

Remedial Repair Method Statement for Powder Coated DuraPost Steel and Alloy Products

1. Purpose

This method statement outlines the procedure for repairing damage to DuraPost powder-coated finishes. The aim is to restore the protective and aesthetic qualities of the coating using approved materials and methods.

2.Materials and Equipment

- DuraPost 400ml Touch-Up Spray Paint (matched to the relevant RAL colour reference)

- Etch Primer (Single Pack Aerosol) – available from standard hardware suppliers

- Zinc-Rich Anti-Corrosion Primer (for exposed ferrous metal, e.g. galvanising etch-primer available from Birkdale)

- Abrasive Paper or Fine Emery Cloth

- Masking Materials (tape and paper)

- Clean Cloths (lint-free)

3. Surface Preparation

- Inspect the damaged are carefully to determine the extent of the coating failure.

- Remove any loose paint and dirt with fine grade abrasive paper.

- Feather the edges of the damaged area by rubbing down until a smooth transition is achieved between the intact coating and bare substrate. This ensures optimal adhesion for the touch-up coating.

- Clean the area thoroughly to remove dust, grease, and debris.

4. Repair Procedure

A.Superficial Damage

- For minor scuffs or light surface scratches:

Apply the DuraPost touch-up spray directly over the affected area.

Ensure even coverage and allow the coating to dry as per manufacturer’s instructions.

B. Deep or Exposed Damage

Where the coating has been penetrated or metal is exposed, proceed as follows:

1. Primer Application:

- Apply a single, even coat of etch primer over the prepared area.

- Allow to dry for approximately 30 minutes (depending on ambient temperature).

2 .Surface Preparation After Priming:

- Lightly rub down any high spots or roughness created by the primer coat.

- Wipe clean to remove dust.

3. Topcoat Application:

- Apply the DuraPost touch-up spray in several light passes to achieve full coverage and a uniform finish.

- The coating is Quick Air Drying (Q.A.D.) and should be touch dry in approximately 15 minutes under normal conditions.

4. Additional Protection for Exposed Metal:

- If ferrous metal is exposed, apply an anti-corrosion zinc galvanising etch primer before proceeding with the above steps.

5. Drying and Curing

- Allow the repaired coating to cure fully before handling.

- Drying times may vary with temperature, humidity, and film thickness.

6. Health and Safety

- Operatives must wear appropriate Personal Protective Equipment (PPE) including:

- Particle mask or respirator (for spray application)

- Safety gloves

- Eye protection

- Ensure adequate ventilation during application.

- Mask surrounding areas to prevent overspray and contamination.

- Dispose of all waste materials in accordance with local environmental regulations.

7. Quality Control

- Inspect the repaired area after drying to ensure a uniform finish and full coverage.

- Check colour consistency against adjacent areas.

- Reapply if necessary to achieve an acceptable visual and protective finish.